Koiri Earthing Voltage Monitoring Unit (EVMU):

Complete Guide, Benefits & Applications Introduction In modern power distribution systems, safety and reliability are inseparable. Every electrical installation—whether an industrial plant, a data center, or a residential complex—Depends on a robust earthing (grounding) system to protect people and equipment.

While earthing itself is a well-known concept, continuous monitoring of the earthing voltage is still underestimated in many facilities.

This is where the Koiri Earthing Voltage Monitoring Unit (EVMU) becomes a game-changer.

Designed to constantly monitor the potential between your equipment and the earth, the EVMU gives early warnings about insulation failures, grounding faults, or dangerous voltage build-ups.

Here’s what I can do for you:

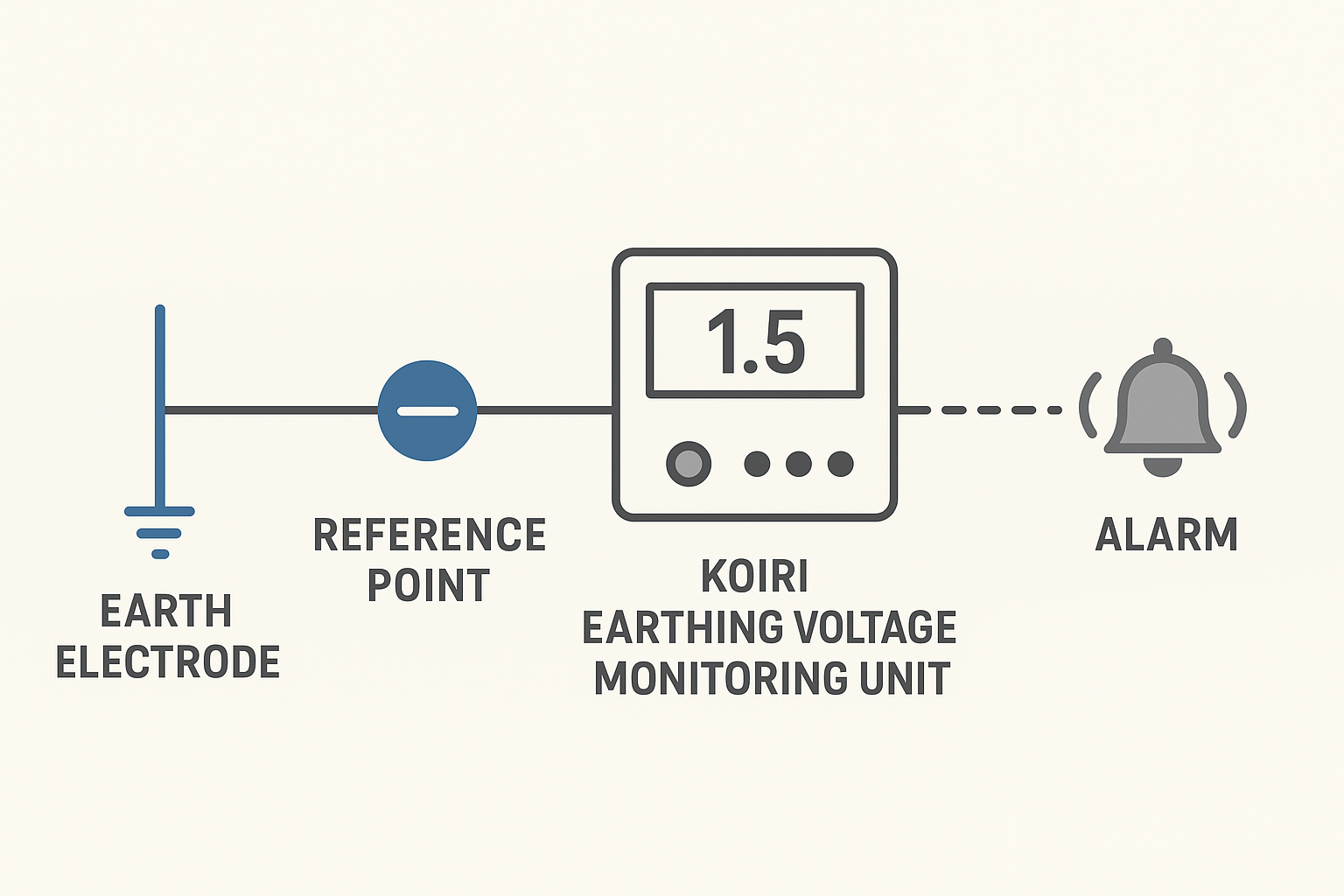

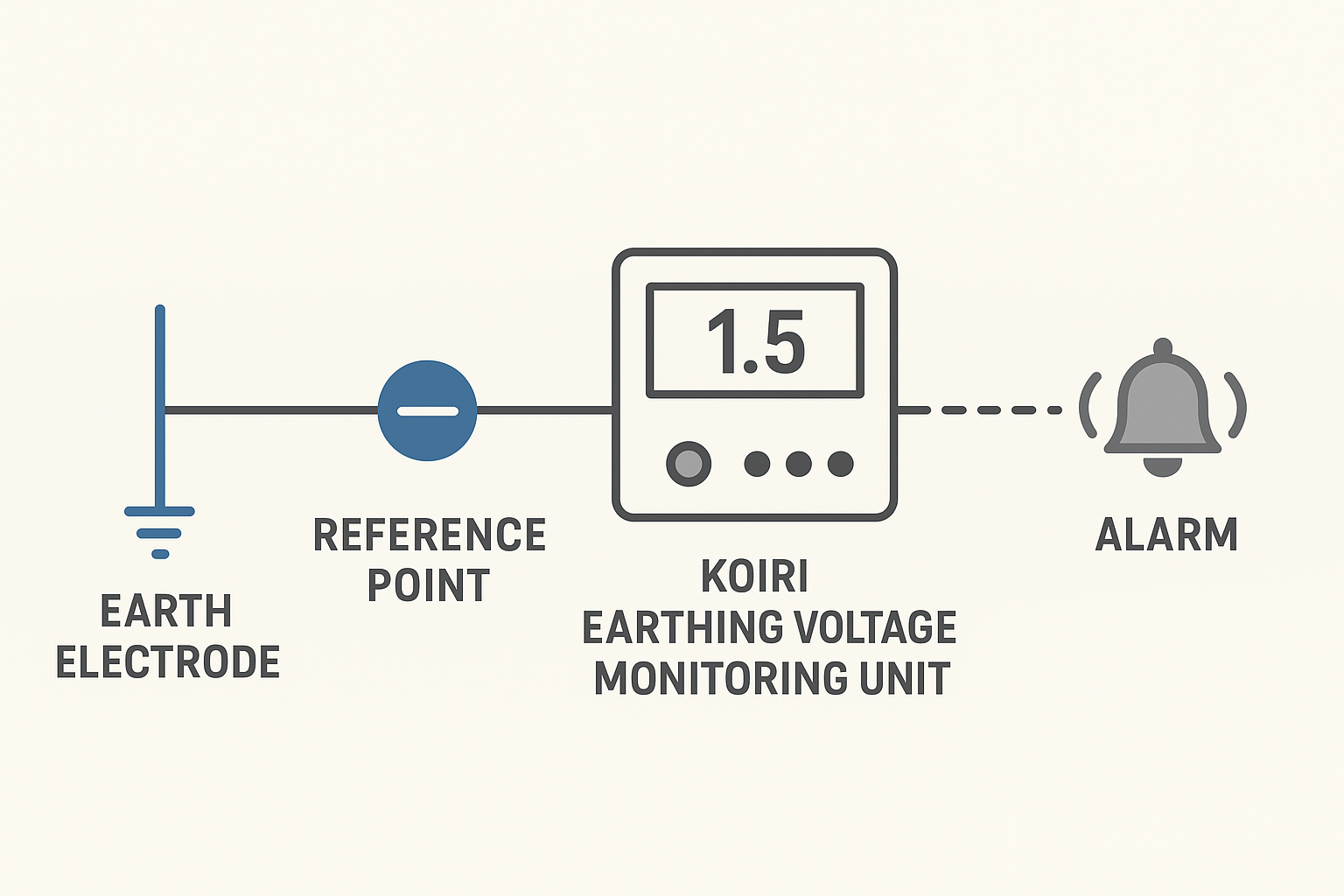

Create a simple block-style diagram showing

- An Earth Electrode

- A Reference Point/Neutral

- The Koiri Earthing Voltage Monitoring Unit in between

- And the Alarm/Display outputs

Use clear arrows to show how the voltage is measured and where the alarm triggers.

Style it like an infographic with icons and minimal text so you can directly embed it in the blog.

In this blog, we’ll cover everything you need to know about Koiri’s EVMU:

How it works, why it matters, its features, benefits, installation, and best practices.

- Understanding Earthing and the Need for Monitoring.

- What is Earthing?

Earthing (or grounding) is the process of connecting parts of an electrical system directly to the ground.

This ensures that in the event of a fault—such as a short circuit, lightning strike, or insulation breakdown—excess current safely dissipates into the earth rather than causing harm to people or damaging equipment.

- The Hidden Risk:

Floating Voltages Even a well-installed earthing system can develop problems over time. Corrosion, loose connections, or damaged conductors can reduce its effectiveness.

When this happens, a potential difference (voltage) may appear between equipment enclosures and the earth. This is known as earthing voltage or ground potential rise.

If left undetected, such voltages can:

Deliver harmful electric shocks to personnel. Cause malfunction or premature failure of sensitive electronics.

- Why Continuous Monitoring Matters Traditional earthing systems are checked only periodically with test instruments.

However, between inspections, conditions can change rapidly. Continuous, real-time monitoring of earthing voltage provides an early warning system, enabling maintenance teams to act before a dangerous incident occurs.

- Introducing the Koiri Earthing Voltage Monitoring Unit (EVMU)

- What is the Koiri EVMU?

The Koiri Earthing Voltage Monitoring Unit (EVMU) is an advanced, microprocessor-based device designed to measure, display, and alert users about voltages present between the system earth and the neutral/ground reference. In simple terms, it acts as the “watchdog” for your grounding network.

- Core Functions Real-Time Monitoring:

Measures earthing voltage continuously. Alarm Generation: Provides audio/visual alerts when voltage exceeds safe limits.

- Target Applications Industrial plants and factories. Data centers and server rooms. Hospitals and critical care units. Substations and switchyards. Large residential or commercial complexes. Essentially, any facility where personnel safety and equipment reliability are critical can benefit from an EVMU.

- How the Koiri EVMU Works

- Sensing Circuit The unit typically connects between the main earthing electrode and a neutral reference point. A high-impedance sensing circuit measures the voltage difference without introducing additional currents into the system.

- Microprocessor Control A built-in microcontroller continuously analyzes the measured voltage. If it exceeds user-set thresholds—say 2 V, 5 V, or 10 V depending on standards—the unit triggers an alarm.

- Alarms & Indicators Koiri’s EVMU comes with: LED or LCD Display: Shows real-time earthing voltage. Audible alert for dangerous conditions. Relay Outputs: Can trip a breaker, activate a signal lamp, or send data to a supervisory system.

- Remote Monitoring Advanced Koiri models include RS-485/Modbus connectivity. This lets engineers view earthing voltage trends on a SCADA, BMS, or energy-management dashboard, ensuring 24/7 visibility.

-

Key Features of Koiri Earthing Voltage Monitoring Unit Feature Benefit Wide Measuring Range (mV to tens of volts) Suitable for diverse installations. Adjustable Thresholds Tailor alarms to site-specific safety standards. High Input Impedance Does not disturb the earthing network. Digital Display Instant visibility of earthing voltage. Audio/Visual Alarms Immediate notification of dangerous conditions.

Relay/Communication Outputs Easy integration with control systems. Compact & Robust Design Long service life even in harsh environments.

- Benefits of Installing a Koiri EVMU

- Enhanced Personnel Safety By detecting dangerous ground voltages before they harm workers, the EVMU significantly reduces the risk of electric shock incidents.

- Protection of Sensitive Equipment Modern electronic devices—automation PLCs, servers, medical equipment—are highly sensitive to ground potential differences. Continuous monitoring prevents costly downtime and damage.

- Early Fault Detection Loose connections, corrosion, or insulation breakdown can all increase earthing voltage. The EVMU acts as an early warning system, allowing timely maintenance.

- Lower Insurance Costs Facilities with proactive safety measures often qualify for lower insurance premiums.

- Installation Guidelines

- Pre-Installation Checks Verify that the earthing system is properly installed. Identify a stable reference point (usually the neutral of the supply or a dedicated reference electrode). Ensure the supply to the unit matches its rated voltage.

- Wiring Connect the sensing terminals to the earthing electrode and the reference point. Wire the power supply separately with proper fusing. Connect alarm outputs or communication cables as required.

- Calibration Set the alarm threshold according to your site’s safety standard. Test the alarm by simulating a fault or using a calibrated voltage source.

- Commissioning Record baseline readings after installation. Train staff to respond to alarms. Schedule periodic functional checks.

- Real-World Use Cases

- Industrial Manufacturing Plant A steel rolling mill with heavy motors experienced frequent unexplained tripping of control systems. After installing a Koiri EVMU, engineers discovered occasional spikes of 8–10 V on the earthing network caused by welding operations. With this insight, they improved the grounding layout and eliminated nuisance trips.

- Data Center A Tier-III data center deployed Koiri EVMUs on every earthing bar. The real-time dashboard allowed facilities engineers to pinpoint developing issues before they threatened uptime, reducing costly downtime risks.

- Hospital ICU Sensitive life-support equipment must have a stable earth reference. A Koiri EVMU provided the hospital’s maintenance team with round-the-clock assurance that no dangerous voltages were developing between earth and equipment enclosures.

- Comparison with Traditional Monitoring Methods Aspect Periodic Testing Koiri EVMU (Continuous) Frequency Once in months or years 24/7, real time Response Time Slow; after fault occurs Instant detection Data Logging Manual Automatic (optional) Safety Assurance Limited High Integration with SCADA Rare Easy

- Integrating EVMU into a Comprehensive Safety System An EVMU is most powerful when combined with: Surge Protection Devices (SPDs): to handle transient overvoltage. Residual Current Devices (RCDs): to trip in case of leakage currents. Earthing Resistance Monitoring: to track electrode resistance over time. SCADA or BMS Systems: for centralized monitoring and alarms. This layered approach creates a robust electrical safety ecosystem.

- Best Practices for Using Koiri EVMU Train Staff: Ensure everyone understands alarm indications and response procedures. Maintain Records: Use the unit’s data logging features or manually record readings to spot trends. Inspect Connections: Periodically check that sensing wires and earth conductors are secure and corrosion-free. Update Thresholds: Adjust alarm limits if your site’s safety requirements change. Firmware Updates (if applicable): Keep the unit’s software up to date.

- Return on Investment (ROI) Though the initial cost of a Koiri EVMU is small compared to major electrical equipment, the savings from prevented downtime, avoided accidents, and reduced insurance premiums can be significant. Facilities often recover the investment within months.

- Future Trends Koiri is continually innovating. Future models may feature: Cloud Connectivity: Remote access via smartphone or web dashboard. Predictive Analytics: AI-based prediction of earthing faults. Wireless Sensors: Easier installation without running new cables. These advances will make earthing voltage monitoring even more accessible and valuable.

- Koiri’s Reputation in Power Quality & Safety Koiri is a well-known name in the power electronics and electrical safety sector, offering products like voltage stabilizers, UPS systems, transformers, and now advanced safety devices such as the Earthing Voltage Monitoring Unit. Their focus on quality, innovation, and customer support makes them a trusted partner for thousands of facilities. Conclusion The Koiri Earthing Voltage Monitoring Unit is more than just a measuring device—it’s an essential safety guardian for any modern electrical installation. By providing continuous, real-time monitoring of earthing voltage, it helps prevent electric shocks, protect sensitive equipment, and ensure compliance with safety standards. Whether you’re responsible for an industrial plant, a data center, a hospital, or a commercial building, installing a Koiri EVMU is a proactive step toward a safer, more reliable electrical environment. In today’s world of increasing reliance on electronics and constant uptime demands, such a device isn’t just an option; it’s a necessity. Quick Takeaways Earthing faults can develop silently and pose severe risks. Koiri EVMU continuously measures and alerts you about unsafe earthing voltages. Features include adjustable thresholds, digital display, alarms, and communication outputs. Benefits: enhanced safety, equipment protection, compliance, and early fault detection. Applications: industrial plants, data centers, hospitals, substations, and more. By investing in the Koiri Earthing Voltage Monitoring Unit, you’re investing in people’s safety, equipment longevity, and operational peace of mind.

Advantages of Koiri Earthing Voltage Monitoring Unit

- Continuous Safety Monitoring

Real-time tracking of earthing voltage ensures any dangerous rise in potential is detected instantly.

- Enhanced Personnel Protection

Reduces the risk of electric shock to workers by giving early warning before unsafe conditions develop.

- Protection of Sensitive Equipment

Prevents malfunctions or damage to PLCs, servers, medical devices, and other sensitive electronics caused by ground potential differences.

- Early Fault Detection

Identifies loose connections, corrosion, insulation failures, or other grounding issues before they escalate into major problems.

- Adjustable Alarm Thresholds

Alarm limits can be set to match the specific safety requirements of each site.

- Cost-Effective Safety Investment

A small upfront cost compared to the expense of equipment damage, downtime, or accidents.

Conclusion

The Koiri Earthing Voltage Monitoring Unit (EVMU) is not just a measuring device—it is a critical safety tool for any facility that depends on a stable and reliable electrical system. By providing real-time monitoring of earthing voltage, it helps protect personnel from electric shocks, safeguards sensitive equipment from malfunction, and ensures compliance with international safety standards. Its adjustable alarms, clear display, and optional communication interfaces make it easy to integrate into existing systems.